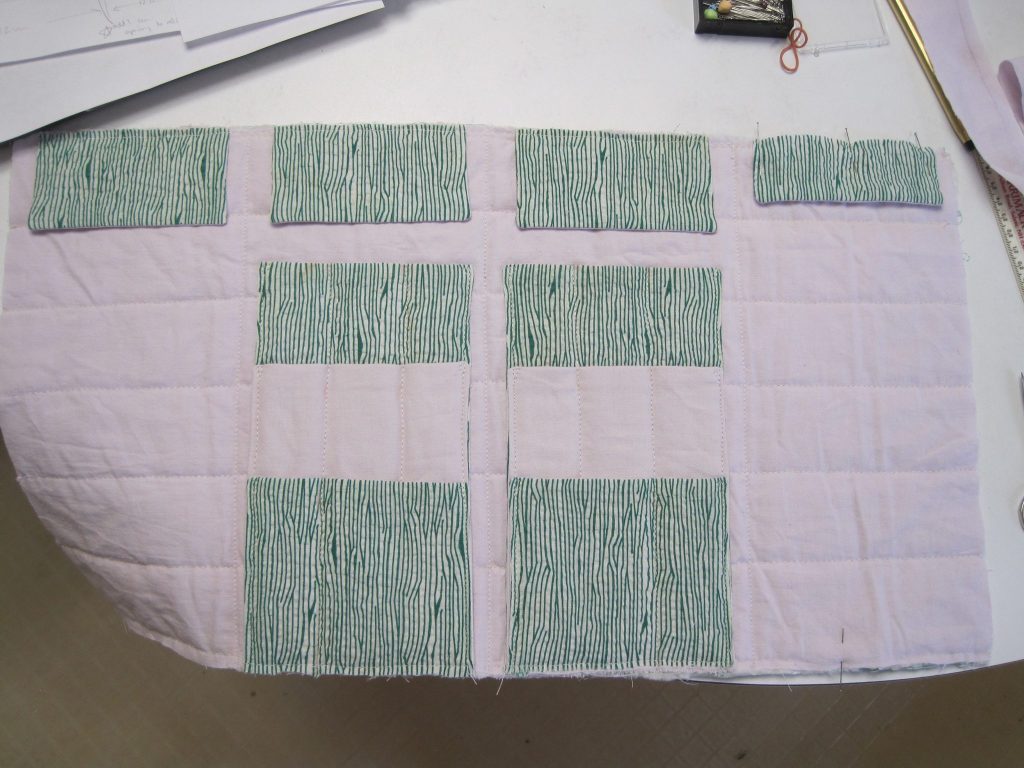

August of last year. Looking fairly lush. I actually had a fair bit more growth later in the season, even pretty late into the fall. The back fence was covered in vines — both my beans and other people’s veggies.

Front to back starting on the left side, I have basil, a pepper (hidden, gifted by a fellow gardener!), teeny baby onions, cherokee purple tomato (gifted by a fellow gardener!), cucumbers, and squash and stuff (volunteer brassica) at the back

Off to the right side are a yew (bush-like) and a box elder (small tree). Plus there’s a full-grown zelkova tree above the benches to the far right. So the plot isn’t too too sunny, especially that front right corner. The spot is too shady for veggies, so I’ve started putting some shade-tolerant native plants (inland sea oats, and volunteer violet transplants) in that corner.

I think the soil is really bad, too. I need to mix more compost in. I was supposed to do that over the winter, but time got away from me. Still planning on going some prep before planting seeds for this upcoming year.

I harvested a couple peppers off of this plant. They weren’t spicy at all. The plant was kindly gifted to me by a fellow gardener. She got the seed from a coworker.

Last harvest of the year (November). There were several pods, more than shown here. I had these beans in soup. I also got a cucumber (not totally sure it was mine. The vines on the fence were all jumbled together. I definitely had planted a cucumber, though), basil, and some other odds and ends.